MOLD-RESISTANT Ductwork coatings

When you’re bothered by musty odors coming out of your AC ductwork, and the inside of the ducts is constructed of fiberglass, ductwork coating is an important tool in mitigating musty odors related to moldy AC systems.

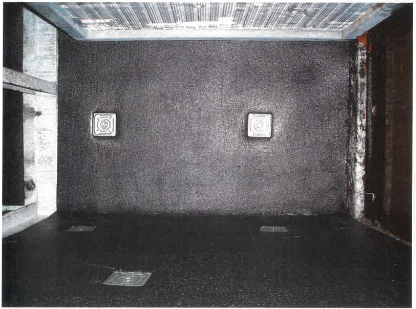

Before Cleaning

After Cleaning

After Cleaning And Coating

Before Cleaning

After Cleaning

After Cleaning And Coating

Before Cleaning

After Cleaning

After Cleaning And Coating

Why we use coatings ?

When coatings are correctly applied, they set up a new air barrier; the conditioned air no longer makes contact with the stained porous surface. This freshly painted surface, containing an EPA registered fungicide to retard future mold growth, is warrantied for the life of the ductwork.

Every air duct has two barriers:

Air Barrier

Keeps the conditioned air in the ductwork until its’ intended destination.

Vapor Barrier

Insulation, usually fiberglass, to prevent the ductwork from condensating

Different types of ductwork utilize these barriers either internally or externally.

When the fiberglass is internal, its porous surface collects and accumulates particulate and microbial accumulations, which can be conducive to mold growth, very much like a sponge. Care must be taken when cleaning these porous duct surfaces to not damage the insulation; however, even when clean, it can remain stained and look visually dirty. When staining remains, the painted coatings are applied after proper cleaning.

The painted coatings perform two functions:

- The coating sets up a new air barrier and dries to form a durable, flexible, moisture-resistant protective coating. The air now is touching a freshly painted surface versus a stained, sponge-like surface. The coating minimizes dirt build-up on the acrylic resin coating surface, which can provide nutrients that feed mold colonies.

- Mold Resistant – Within the painted coating is an EPA registered fungicide which retards future mold growth

The primary purposes of the coatings are to provide a surface that is not conducive to capturing or retaining particulate that could support future microbial activity, smooth the bore of HVAC to enhance air flow, and improve future cleaning capability. This product contains an EPA-registered active ingredient to deter future fungal activity on or in the coating film. However, inhibition of future microbial activity is dependent on proper maintenance. When insulation is found to be wet or significantly degraded, replacement is recommended.

Before removal of the contaminated insulation liner

After relining with IMCOA closed cell insulation